Drilling Technology

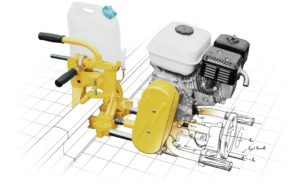

RAIL DRILLING MACHINE PR7

Robust, quick & easy to use, the PR7 rail drilling machine guarantees optimisation and ease of use. The PR7 offers you cost benefits with low maintenance costs, benefiting from its sturdy design and high-quality engine

Helicoidal drill bits allow resharpening keeping your operational costs low and productivity high.

LIGHTWEIGHT COMPACT RAIL DRILLING MACHINE PR2

Ultra-lightweight due to its compact design and the use of hollow drill bits User-friendly and easy to position to ensure your swift & controlled drilling Optimised cost/lifespan ratio thanks to its low maintenance requirements and sturdiness, minimising maintenance costs and saving you money over its lifetime

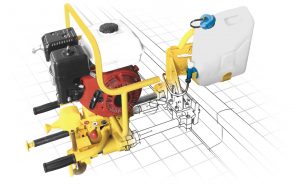

RAIL DRILLING MACHINE PR8

The PR8 provides you maximum drilling with minimal effort due to the 3-speed automatic feeding system. The PR8 keeps your maintenance costs low, benefiting from its sturdy design and high-quality engine. Helicoidal drill bits allow resharpening keeping your operational costs low and productivity high.

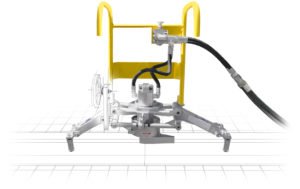

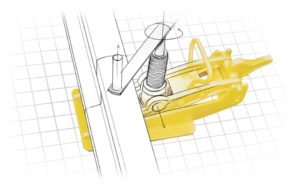

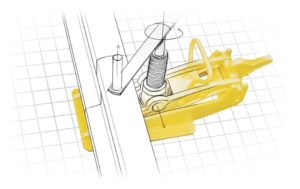

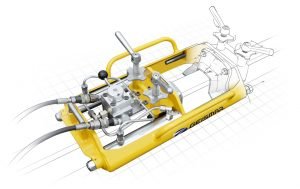

LIGHTWEIGHT & COMPACT RAIL DRILLING MACHINE PRZ

Quick and easy to set up with its universal vice, fast lever catch and interchangeable carbide tips.Suitable for all types of rail, including the hardest and thickest rails thanks to its carbide drill bits and the longest drilling stroke of any machine on the market. Guarantees you high-end quality drilling with its carbide tips providing you with a perfect surface finish and reducing the risk of rail cracks.

GRINDING TECHNOLOGY

FROG POINT AND CHECK RAIL GRINDING MACHINE MC3

Specifically designed for grinding operations through switches and crossings and either side of the rail head Additionally, “narrow type” grinding stones allow you to grind even in the most confined areas around check and grooved rails. All mechanical parts are made from special steel to increase the lifespan of the machine thereby minimising your maintenance costs. The design offers you excellent visibility of the grinding area facilitating the operation to ensure a more accurate finish.

LIGHTWEIGHT HYDRAULIC RAIL PROFILE GRINDER MP5H

Grinds the rail head, the welded rail joint, the radius edge and the sides in one operation Easy to use, light and accurate. the perfect cost-effective grinder. Hydraulically powered from either a mobile power pack, a vehicle or a track motorcar, the MP5H provides excellent visibility of the grinding.

RAIL PROFILE GRINDING MACHINE MP6

Offers you perfect rail profile grinding, giving you up to 90° and 180° rotation about the rail head. Designed to allow you to grind the running surfaces of turnouts you are assured of additional safety by a centrifugal clutch that stops the grindstone when the engine is idling use friendly due to its special adjustable guiding arms, allowing for a high-quality finish.

RAIL PROFILE GRINDING MACHINE MP6

Offers you perfect rail profile grinding, giving you up to 90° and 180° rotation about the rail head. Designed to allow you to grind the running surfaces of turnouts you are assured of additional safety by a centrifugal clutch that stops the grindstone when the engine is idling use friendly due to its special adjustable guiding arms, allowing for a high-quality finish.

RAIL LOADER WITH MOTORIZED WINCH CR

Powerful and compact provides an efficient and modular solution for grinding operations on track. Its advanced road-rail system means the V2R-M can be delivered and set up on-site quickly Ideal for urban networks, our Road-Rail grinding vehicle gives you the flexibility to perform preventive grinding operations as well as the correction of localized corrugation and rail profile. Thanks to its remote control, the grinding module is easy and safe to use. Moreover, grindstone life is maximised because the profile is analysed and the optimum grinding depth is set. The versatility of our V2R Road-Rail system means we can provide vehicle designs to assist you in many operations such as equipment handling, track cleaning, brushing or even vehicle recovery.

RAIL PROFILE GRINDING MP12

The world’s best-known rail profile grinder guarantees you accurate grinding by the monobloc frame made of high resistance alloy. The design of the machine allows you accurate and stable profile grinding up to 90° and 180° about the rail head by rotation of the machine using its turning device and its inclinable operating arm. The MP12 gives you exceptional grinding performance with its powerful engine. Good visibility of the grinding area assures you of a high-quality finish.

VERTICAL RAIL & SWITCH GRINDING MACHINE MV3

The MV3 is world-renowned to grind the head of all flat bottom rails and check rails in any type of switch or crossing. The adjusting hand wheels allow you quick and accurate operation. Ergonomic grinding is achievable even in turnouts, with excellent visibility of the grinding area providing you with a high-quality finish.

HANDLING TECHNOLOGY

RAIL LOADER WITH MOTORIZED WINCH CR

Rail loader with motorized winch model CR-FP will allow you thanks to an easy set-up on any standard flat wagons to load & unload rails from both sides of the track. The high level of customisation and the modularity of the CR-FP makes it key equipment for all rail loading and unloading jobs thanks to its pivoting column or fixed column to be fitted on each side of the wagon. A set of 12 rail loaders gives you the possibility to handle safely up to 120 meters long welded rails thanks to its self-tightening clamps, its locking of the jib in transport position and the possibility to use the remote control for synchronized movements.

ROLLER RAIL CLAMP FOR LONG WELDED RAILS OMR

You will find the OMR to be the most simple and most efficient device on the market for longitudinal rail threading.The OMR grips the rail by 4 rollers mounted on bearings with a quick locking device.It is compatible with most road/rail loader/excavators, making it a versatile asset to your workforce.

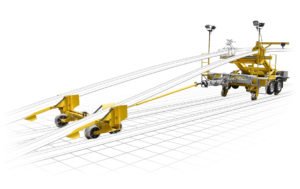

LWR MOBILE UNLOADING SYSTEM EMD

The LWR Mobile Unloading System EMD consists of either a rail-road or a rail-bounded trailer which is connected via an adjustable tow bar to a Long Welded Rails Wagon on which is mounted a wagon end guiding assembly. A second adjustable tow bar connects a forward guiding trolley to the road-rail trailer. Easy to operate, the road-rail version of the EMD gives you access to the worksite by road or by rail. Autonomous and un-reliant on the rail transporting train the EMD is an efficient way to unload long welded rails. During operation, the rails are continually guided and can be unloaded into 3 possible positions depending on local standards.

RAIL THREADER MPR

You can minimise operational costs with the MPR which is operated by a single worker. The machine can position up to 2 long welded rails simultaneously You have assured of the safe operation of the clamp which is designed to remain closed giving you peace of mind while operating the machine.The MPR is self-propelled and can off-track without additional lifting equipment

CUTTING TECHNOLOGY

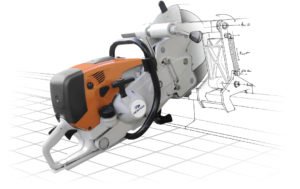

LIGHT-WEIGHT ABRASIVE RAIL SAW MTZ 350 & 400

Easy & quick to set up, it guarantees you the perfect cut every single time Cut within seconds with its exceptional blade speed. The Patented Stihl technology requires half the usual maintenance, saving you money over its extended lifetime. With low vibrations & low noise levels, it delivers the utmost comfort in the roughest conditions.

LIGHT-WEIGHT BATTERY-POWERED ABRASIVE RAIL SAW

The Activation MTZ is the most powerful and ergonomic electric rail saw in the market, you find MTZ’s traditional easy and quick set-up enhanced by an advanced turnaround system that delivers you the perfect cut every single time. You get 6 cuts to a battery charge and cuts within seconds with its exceptional blade speed. You and your surrounding environment benefit from Zero Gas emission for underground or tunnel work and Very low acoustic impact for night work in urban areas. Saves you money over its extended lifetime; lasting longer and providing very low operation and maintenance costs.

MANUAL EQUIPMENT

SCREW LIFTING JACK CRV-96

Robust design & easy operation for lifting track.The screw operation provides you with accurate precision lifting.The reliable & simplified design requires minimal maintenance and hence assures you of greatly reduced maintenance costs over the lifetime of this lifting jack

HYDRAULIC JACK FOR LIFTING & SLEWING RAIL CH65

Robust & multi-function, you can use this jack for multiple purposes (lifting, slewing…)The high lifting stroke allows you to work in various conditions with ease of operation.The CH65’s hydraulic action makes it easy to operate in even the most difficult of circumstances.

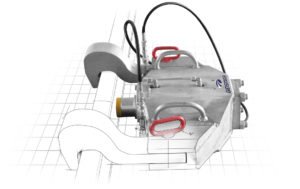

SHEARING TECHNOLOGY

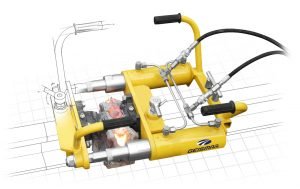

MODULAR WELD SHEAR ESN 3

You are assured of a clean cut with the powerful ESN 3 thanks to an evenly distributed shearing force. The cutting blades and guides are adjustable so you can optimise the shearing of the weld. Only minimal final grinding is necessary after shearing thereby saving you time and money.

WELD SHEAR ESN 4

The powerful ESN4 is designed to provide an evenly distributed cutting force, ensuring you a clean cut.The cutting blades and guides are adjustable to provide you with maximized and accurate shearing You can operate the ESN4s in plain line and in limited access to switches and crossings.

BENDING TECHNOLOGY

LIGHTWEIGHT HYDRAULIC RAIL AND SWITCHBLADE STRAIGHTENER JLP75

The multi-function JLP75 rail bender is composed of a robust light alloy frame and offers you a range of rail bending applications.The modular design allows you to vertically and horizontally bend or straighten flat bottom rails, switchblades and contact rails with the use of various bending & straightening kits.The machine has a powerful bending and straightening capacity of 75 kN