HANDLING TECHNOLOGY

RAIL HANDLING MANUAL GANTRY PMR

The PMR offers you the most simple method to replace rails or parts of switches

Light, robust and easily adjustable providing your operators with excellent working comfort.The PMR utilises dismountable parts enhancing easy transportation and a quick set up on site

RAIL LIFTING TROLLEY L2R 522

The L2R 522 makes it effortless to accurately lift rails to replace chairs or baseplates as well as install rollers for destressing work

While it can easily go off-track, you will find it this unit easy to use thanks to an efficient design.In addition, you can safely immobilize the machine using a safety braking device actuated from a handle which makes this machine safe equipment to use.

RAIL CHANGER PSR

You will find using the PSR to be the most simple method to change or to move rails laterally due to an efficient design.It offers you user-friendly operation with its lightweight and robust design but is easily adjustable for a good working height and horizontal positioning.Suitable for all environments, its versatile design assures you perfect operation with any flat bottom or grooved rails

RAIL THREADER MPR

You can minimise operational costs with the MPR which is operated by a single worker. The machine can position up to 2 long welded rails simultaneously

You have assured of safe operation the clamp which is designed to remain closed giving you peace of mind while operating the machine.The MPR is self-propelled and can off-track without additional lifting equipment

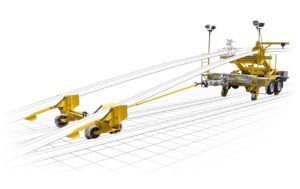

LWR MOBILE UNLOADING SYSTEM EMD

The LWR Mobile Unloading System EMD consists of either a rail-road or a rail bounded trailer which is connected via an adjustable tow bar to a Long Welded Rails Wagon on which is mounted a wagon end guiding assembly. A second adjustable tow bar connects a forward guiding trolley to the road-rail trailer.

Easy to operate, the road-rail version of the EMD gives you access to the worksite by road or by rail Autonomous and un-reliant on the rail transporting train the EMD is an efficient way to unload long welded rails During operation, the rails are continually guided and can be unloaded into 3 possible positions depending on local standards

LEVELING & SLEWING MACHINE LNR 528 & LNR 529

High lifting capacity suitable for one or two track lines Compatible in all worksite configurations, the LNR modernizes levelling and slewing works. Ensuring work in full safety condition, you can adjust the speed of work to maximize the output thanks to our user-friendly remote control.

RAIL LOADER WITH MOTORIZED WINCH CR

Rail loader with motorized winch model CR-FP will allow you thanks to an easy set up on any standard flat wagons to load & unload rails from both sides of track. The high level of customisation and the modularity of the CR-FP makes it key equipment for all rail loading and unloading jobs thanks to its pivoting column or fixed column to be fitted on each side of the wagon. A set of 12 rail loaders gives you the possibility to handle safely up to 120 meters long welded rails thanks to its self-tightening clamps, it’s locking of the jib in transport position and the possibility to use the remote control for synchronized movements.

LAYING & RENEWING TECHNOLOGY

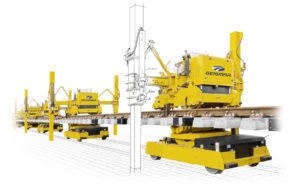

TURNOUTS AND TRACK LAYING SYSTEM PEM-LEM

The most used method worldwide for replacing turnouts, you can use the machines for any turnout length & type merely by adjusting the number of PEM-LEM sets. The PEM-LEM allows the installation of turnouts either by slewing them from an adjacent site or by transporting them on LEMs (motorized transportation trolleys) on track from the assembly site to the installation site.The PEM-LEM are designed to keep you safe with a user-friendly remote control to operate the machines

TRACK PANEL LAYING METHOD

S2PV The S2PV gives you an efficient track laying methodology to achieve a high output 200 meters per hour laying 36m long plain track panels. Compatibility with other track laying methods (type PEM LEM & SPAC) and the ability to work in any type of network makes the S2PV a must-have for quick and efficient installation of the track.The S2PV ensures a safe work environment with a user-friendly remote control

TRACK & TURNOUT PANEL LAYING METHOD FOR TILTING WAGON

PWP The PWP offers you the methodology to work quickly and efficiently in a safe manner to lay track, switches or turnouts from a panel transportation tilting wagon. The machines are compatible with other track-laying methods (such as PEM-LEM & SPAC) and offer you the ability to work on any network in a wide variety of applications. The PWP’s unique design helps to avoid the deformation of turnouts during handling and installation. Keeping your safety first, the PWP is capable of working in safe conditions with a user-friendly remote control, providing accuracy and safety together

TRACK SWITCH LAYING SYSTEM SPAC SYSTEMS

The versatility of this system offers you the operational capability to combine some of these elements for other track laying systems (such as PEM XL / LEM or S2PV) to suit various track-laying methods. Its modular conception enables to installation up to 45 meters/45 tons of switches with a very high degree of safety for the operator thanks to the remote control..The high output performance of the SPAC system offers you the advantage of installing a switch in less than an hour.

HYDRAULIC GANTRIES FOR TRACK LAYING AND RENEWAL PTH 350 & 500

The hydraulic gantries model PTH ensures an efficient track laying methodology to achieve a high output up to 450 meters per hour of new track or up to 350 meters in case of track renewal. With a powerful lifting capacity of up to 30,000 daN per pair, the range of hydraulic gantries model PTH can easily handle all track panels up to 36 meters and can handle up to 60 concrete sleepers with a dedicated sleeper beam. Versatile with a large choice of sleeper beams equipped with either chains or hydraulic paddles suitable for all kinds of sleepers, timber, concrete or steel Suitable for all gauges, the simple and robust design of the PTH incorporates a high level of safety to ensure the security your operators as well as ensuring low maintenance costs The PTH gantries are easily transported on-site using rotating turrets installed on a flat wagon and compatible with most railway gauges

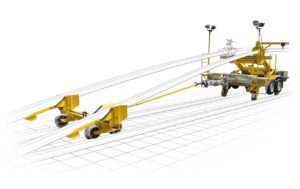

LWR MOBILE UNLOADING SYSTEM EMD

The LWR Mobile Unloading System EMD consists of either a rail-road or a rail bounded trailer which is connected via an adjustable tow bar to a Long Welded Rails Wagon on which is mounted a wagon end guiding assembly. A second adjustable tow bar connects a forward guiding trolley to the road-rail trailer.

Easy to operate, the road-rail version of the EMD gives you access to the worksite by road or by rail Autonomous and un-reliant on the rail transporting train the EMD is an efficient way to unload long welded rails During operation, the rails are continually guided and can be unloaded into 3 possible positions depending on local standards.